Our Process

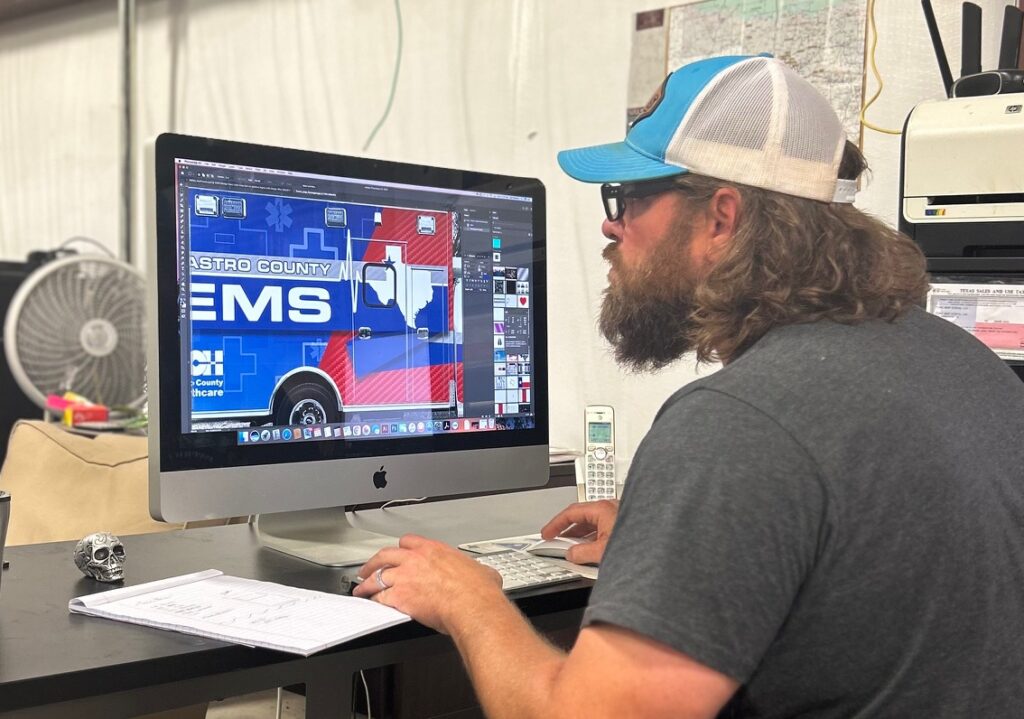

Design

Every vinyl wrap that we produce begins with design. From brand new graphic packages to meticulously recreating existing graphics, our designers work carefully at each step to gather the accurate information to create the Graphics Proof. We create original new packages and also work with nationally established brand standards to ensure accuracy. Many of our customers in other states, so we often mail so often we often overnight color samples printed on the correct reflective or autowrap material to ensure the colors are accurate to specification.

Color Samples

Graphics Proof

We keep two Mutoh ValueJet 1624X EcoSolvent wide-format printers humming all day long. We can print up to 60” wide material, and often are printing reflective material and Autowrap material at the same time to maximize productivity. We carefully maintain our printers to ensure that the imaging is pristine. We calibrate the color profiles periodically so the colors print accurately. Then the prints are carefully laminate to protect from UV rays, and plotted and prepared for installation.

Mutoh VJ1624X Printers

Mutoh VJ1624X Printers

Mutoh Plotters

Graphics Proof

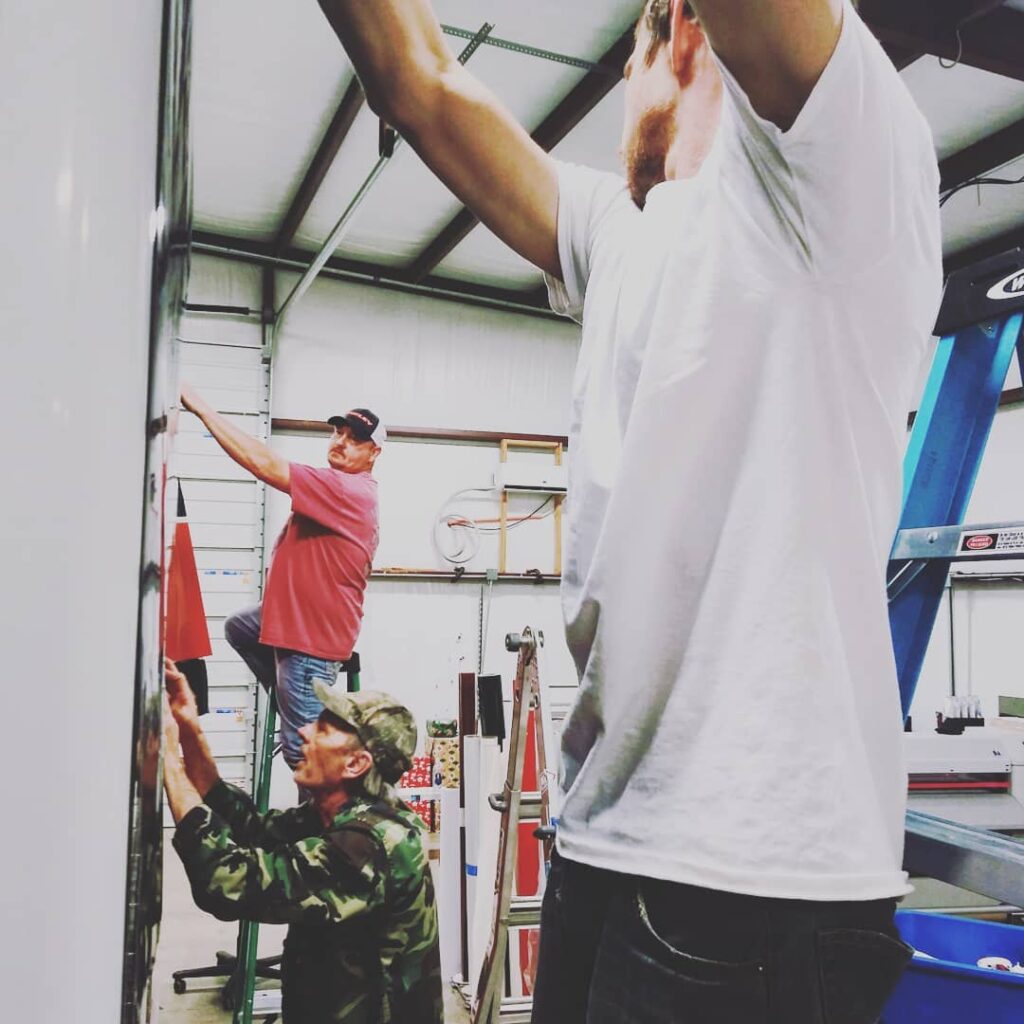

Install

We install our vinyl graphics with utmost carefulness and attenetion to detail. remove lights, hardware and fenders. We clean every surface multiple times including inside hinges so the wrap will stick clean, will look great and will last. We strive for perfection to ensure durability, accuracy and no reprinting or rework issues. We are experts at our craft and nothing gives us more satisfaction than excellent work that thrill our customers. Texas Wrap would like to thank all the talented graphics installers we’ve worked with over the years.

Going ABOVE and BEYOND is part of our regular day at Texas Wrap. What sets our wrap installation apart from the rest of the wrap shops?

The Texas Wrap Advantage: Why are our wraps

The Texas Wrap Advantage:

Why are our wraps

BETTER?

Hardware Removal

All lights, trim, covers and moulding is taken off so cuts don’t show and start peeling quickly.

Edges Are Not Cut Flush

Most shops lat a vinyl piece and cut it flush with doors and windows. The edge shows and looks bad and peels quickly. We tuck material inside door panels so the wrap LASTS and looks BETTER from all angles.

Horizontal Panels

Other shops print several vertical panels to wrap a large surface in order to cut risk of wasting material. This makes EVERY edge a potential peeler as moisture and dirt get in. It also makes the image harder to register. WE print the full panel in one horizontal piece with a 1” overlap if it requires two pieces. This looks far superior, lasts longer, and keeps the seem below or above eye level.